| Description |

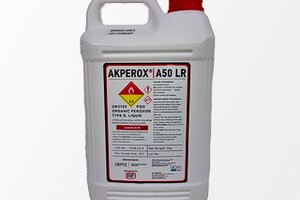

AKPEROX A50 LR is a medium reactivity, general purpose MEKP for curing unsaturated polyester (UP) resins at room temperature. |

APEROX LPT is a mixture of MEKP in diisobutyl phthalate. LPT is a general purpose MEKP recommended for curing unsaturated polyester resins and vinyl ester resins. Suitable in gelcoats, given low hydrogen peroxide and water content. |

AKPEROX C-50 is a peroxide mixture based on cumene hydroperoxide. AKPEROX C-50 is especially developed for the cure vinylester or phenacryl resins in Combination with a cobalt accelerator. Packaging |

Mixture of methyl ethyl ketone peroxide and cumyl hydroperoxide. AKPEROX CMP75 is a liquid polymerization initiator for the room temperature cure with slower gel time than MEKP, better final cure and low impurity levels advantages. |

Disappearing Red Peroxide Dye Concentrates |

| Technical Data Sheet |

|

|

|

|

|

| Safety Data Sheet |

|

|

|

|

|

| Benefits |

AKPEROX A50 is a general purpose MEKP for curing unsaturated polyester (UP) resins at room temperature. Generally used in resins containing metal salts such as cobalt. Suitable for the curing of gelcoat resins, laminating & castings resins, vinylester resins. Further it is very suitable for FRP pipe production. In regard to gelcoat applications it performs very well due to low water and hydrogen peroxide content. |

AKPEROX LPT is a general purpose MEKP for curing unsaturated polyester (UP) resins at room and high temperatures. In a comparison with other Ketone peroxides, LPT provides longer gelling time. Particularly suitable for longer gelling time needed applications as well as production of big parts and coiling type pipe production. Recommended to be used with vinylester resins. Suitable for gelcoat applications in point of low Hydrogen Peroxide besides low water content in order to prevent bubbles and cracks for surface quality |

AKPEROX C-50 is a peroxide mixture based on cumene hydroperoxide. C-50 exhibits excellent cure when used with cobalt promoted vinyl ester resins. Further the vinyl ester resin shows low or no gas / bubble formation and a lower peak exotherm. Especially suitable in vinyl ester laminates require minimal shrinkage, or where the laminate is of varying thickness varying. |

Able to be used very successfully with both vinyl ester and polyester resins, as the final cure will be excellent. In regard to polyester resins CMP75 exhibits longer geltimes, lower impurity levels and lower peak exotherm. Applications requiring low shrinkage and exotherms, whilst operating at ambient temperatures will benefit from CMP75. |

AKPA Performance Red Dye concentrates are available for selected AKPEROX peroxide products to enable the user the ensure that the peroxide cure initiator /catalyst is being uniformly mixed and applied in unsaturated polyester and vinyl ester resins.These dye concentrates are available in permanent or fading formulations as described above. Non-fading red dye for most standard,low water content ketone peroxides.Ready mixtures of peroxides are stable for several months if stored properly.Peroxide products for which this is a suitable dye can be pre-dyed at the time of manufacture for selected products or added at point of use. |

| Warning |

Please ensure you thoroughly read the safety data sheet (SDS), before using or storing this product. |

Please ensure you thoroughly read the safety data sheet (SDS), before using or storing this product. |

Please ensure you thoroughly read the safety data sheet (SDS), before using or storing this product. |

Please ensure you thoroughly read the safety data sheet (SDS), before using or storing this product |

Please ensure you thoroughly read the safety data sheet (SDS). |