| Description |

Polymal- 8856 resin is general purpose, medium reactivity unsaturated, orthophthalic polyester resin. Available in unwaxed, waxed and low styrene emission XLE. It is suited for hand layup and spray up lamination. |

Polymal-8225 Laminating Resin of Lower Reactivity orthophthalic resin. Available in unwaxed, waxed and low styrene emission XLE. Suitable for general lamination and for thicker laminates. |

Polymal-835 Laminating Resin of Higher Reactivity orthophthalic resin. Available in unwaxed, waxed and low styrene emission XLE. Suitable for general lamination and for thinner laminates and /or cooler climates. |

Poliset 845WT-U is fillable, general purpose thixothropic, non accelerated, waxed type of unsaturated polyester resin of orthophthalic. It exhibits good tack free property upon curing and good wetting properties with fillers. |

PS-610PT is thixothropic, pre-promoted, non-waxed type unsaturated isophthalic polyester resin suitable for various lining and FRP laminating that require heat and chemical resistance. Available in unwaxed, waxed and low styrene emission XLE. |

Polymal 5863PT is availabe as unwaxed, waxed, XLE and is accelerated and thixothropic unsaturated polyester resin based on terephthalic /NPG. It is high molecular weight with good chemical & heat resistance. |

| Technical Data Sheet |

|

|

|

|

|

|

| Safety Data Sheet |

|

|

|

|

|

|

| Application Processes |

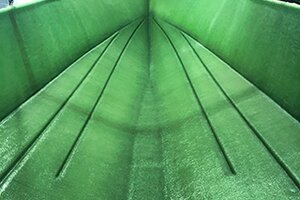

Spray-up and hand layup for the manufacture of boats, automotive, water tanks, agricultural equipment, enclosures, etc.. |

Spray-up and hand layup for the manufacture of boats, automotive, water tanks, agricultural equipment, enclosures, etc.. |

Spray-up and hand layup for the manufacture of boats, automotive, water tanks, agricultural equipment, enclosures, etc.. |

845 fillable resin, can used for making a variety of glass fiber reinforced plastic products. This is especially so where a cost competitive, high rigidity, high filler content resin is needed. |

Suitable for chemical plants and pipes, container of fuels, hydrocarbons, glycols and foodstuffs. |

PS-5863 is suitable especially for applications requiring the containment of water, acids of various types, salt and exhibit good performance in the storage and handling of polar solvents. |

| Benefits |

An economic, low viscosity, exceptionally low secondary tack, thixotropic resin offering fast wet-out, low styrene emission in (XLE) format. 8856 is thixotropic, promoted resin, that is ready to use. It readily wets out glass fibre with easy de-foaming. |

Economic, low viscosity, thixotropic resin offering fast wet-out, low styrene emission in (XLE) format. Recommended for thicker laminates and warmer climates |

An economic, low viscosity, thixotropic resin offering fast wet-out, low styrene emission in (XLE) format. Recommended for thinner laminates and cooler climates |

845 is an economic, low viscosity, thixotropic resin offering ease of lamination and high filler loading capabilities. |

Excellent laminating qualities with low foaming. Low tack, good clarity with good physical and chemical performance. This resin has excellent heat resistance and chemical and water resistance. It has good affinity for glass fibers with no whitening.. |

|

| Chemical Structure |

Ortho |

Ortho |

Ortho |

Ortho |

Isophthalic |

|

| Tensile Strength MPa |

88 |

60 |

60 |

70 |

47 |

|

| Tensile Modulus GPa |

4.8 |

4.0 |

4.0 |

3.7 |

3.8 |

|

| Flexural Strength MPa |

153 |

98 |

98 |

137 |

98 |

|

| Flexural Modulus GPa |

4.2 |

4.1 |

4.1 |

3.7 |

3.8 |

|

| Elongation % |

2.5% |

3.0% |

3.0% |

2.5% |

1.3% |

|

| Heat Distortion Temperature |

65 |

75C |

75C |

80 °C |

94 |

|

| Acid Value |

15-30 |

15-20 |

15-20 |

N/AA |

10-20 |

|

| Appearance |

Light Green |

Pinkish |

Pinkish |

Hazy light Yellw |

Purple |

|

| Viscosity cps@25C |

650-750 |

550-650 |

550-650 |

250 - 350 |

500-600 |

|

| Styrene Content |

48-53 |

40-48% |

40-48% |

49 - 53 |

45 |

|

| Certificates |

Lloyds Under Application |

Lloyds ✔ |

Lloyds ✔ |

N/A |

- |

|

| LSE Available |

Yes |

Yes |

Yes |

Yes |

Yes |

|

| Geltime@1.5% A50 MEKP@ 25°C |

Standard grades 20/30/45/60/75 min |

Standard grades 20/30/45/60/75 min |

Standard grades 20/30/45/60/75 min |

Standard grades 20/30/45/60/75 min |

Standard grades 20/30/45/60/75 min |

|